| Item | Lvkun Oil Sludge Treatment Unique Features |

| Maximum raw material | It has strong adaptability to raw materials, and can treat all kinds of oil sludge such as floor sludge, oil refinery sludge and tank bottom sludge. It can be directly processed in the production line, which greatly reduces the cost of sludge disposal and simplifies the operation process |

| Lowest disposal cost | The latest pyrolysis technology is non-coking, uniform heating, and can complete gas-liquid-solid separation at a lower temperature. The non-condensable gas is purified used as fuel to heating reactor. The cooling adopts water circulation and process flow is simple |

| Maximum resource recovery | Almost all of the oil part of the recyclable oil sludge, the pyrolysis oil is directly used as fuel, and solid slag can be used as building materials |

| Minimal environmental factors | The operation of the production line is not affected by external environmental factors such as weather, and can realize long-term uninterrupted and stable continuous operation |

| EU and US Emission Standard | Emission gas of the production line has been tested, and all emission indicators comply with EU and US EPA standards |

| PLC Control | The whole production line adopts PLC control, prompts and alarms to ensure safe operation of equipment |

| Final Product | Usage |

| Pyrolysis oil (45-55%) | 1. Can be reprocessed by oil distillation machine to extract diesel if the customers want to sell it at a better price. 2. The diesel can be used as fuel oil to many large types of machinery 3. Can be recycled to the furnace for heating the reactor 4. Can be sold directly, widely used in ceramic factory, cement factory, steel factory and so on 5. Can be used directly in the heavy oil generator to get electricity |

| Carbon black (30-35%) | 1. Can be reprocessed through carbon black grinding plant, such as use in rubber industry , black dye, paint 2. Used in tire manufacturing, cables, conveyor belts, soles and other rubber and plastic products 3. To make briquette and construction brick 4. Sell directly |

| Combustible gas(8%-10%) | 1. Can be reused to supply heat for the pyrolysis reactor 2. Can generator to power electricity 3. Compressed into liquid gas |

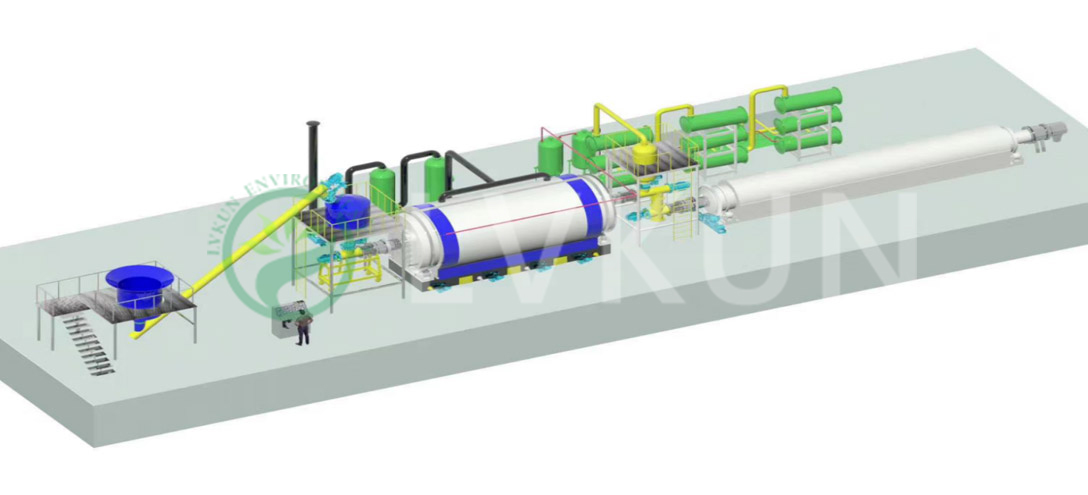

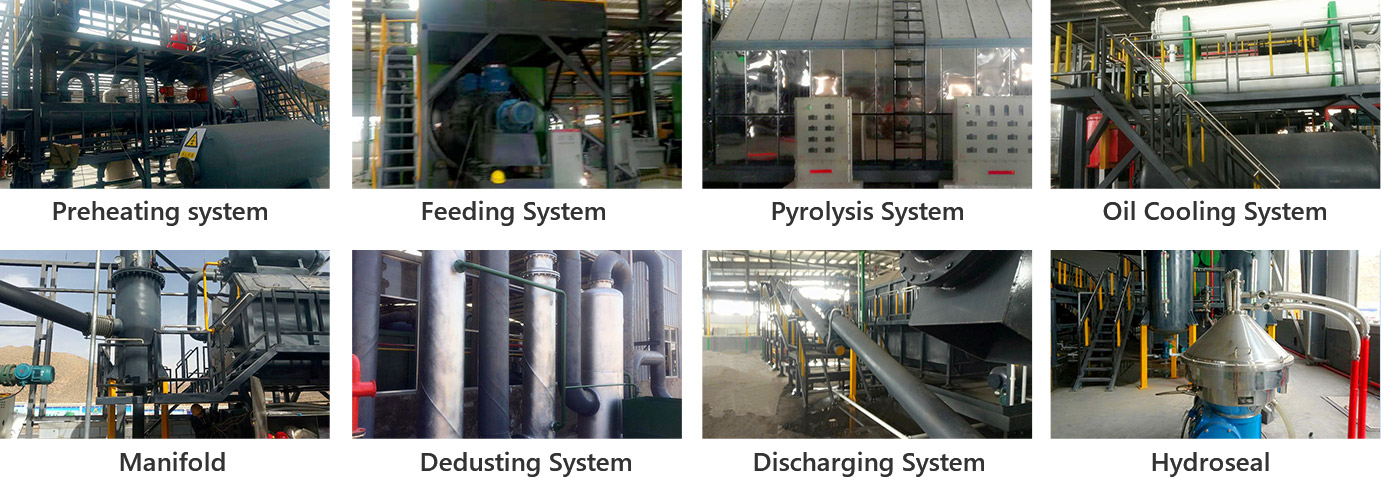

| Item | Function |

| Reactor | High temperature pyrolysis under full closed condition,convert to fuel oil |

| Manifold | Light oil gas go up and heavy oil gas go down, height affects the quality of oil and gas |

| Oil Cooling | Large and enough cooling area to gurantee the effection of oil cooling , and takes short time to overhaul compared with other suppliers |

| Dedusting | Ensure the flue emmission meet European Standard |

| Hydroseal | Prevent fire back to oil gas pipes , ensure pyrolysis machine and staff’s safety |

| Discharging | To discharging carbon black automatically with full -close ,more environmental |

| Model | LKP-6 | LKP-8 | LKP-12 | LKP-15 | LKP-20 | LKP-40 |

| Size of Reactor(M) | D2.2*L6.0 | D2.7*L6.2 | D2.8*L6..6 | D2.8*L7.1 | D2.8*L8.0 | L12.5*W2.2*H2.5 |

| Daily Capacity | 5-6T/D | 8T/D | 10-12T/D | 15T/D | 16-20T/D | 30-40T/D |

| Power | 24kw/h | 30kw/h | 36kw/h | 40kw/h | 56kw/h | 108kw/h |

| Working Method | Intermittent/Batch | Semi-continuous | Full-continuous | |||

| Heating Material | Natural gas/Oil/Wood/Coal/LPG and so on | |||||

| Reactor Thickness | 14mm/16mm/18mm | |||||

| Rotate Speed of Reactor | 0.4turn/minute | |||||

| Cooling Method | Water cycling cooling | |||||

| Labor Required | 4-6 person in two or three shifts | |||||

| Item | Lvkun Oil Sludge Treatment Process |

| 1 | The dried oil sludge is transported to the feeder of pyrolysis reactor through a screw conveyor, and closed enter into the pyrolysis reactor |

| 2 | Under an oxygen-free, high temperature and sealed environment, the three main components of oil sludge, oil, sludge and non-condensable gas will be decomposed |

| 3 | Oil gas and non-condensable gas enter oil condenser from manifold, the liquid oil is filtered enters oil storage system, and non-condensable gas enters the combustion system after hydroseal to heating reactor |

| 4 | After pyrolysis, solid components such as slag are conveyed out of the system after cooling through the second slag sealing system |

| 5 | The flue gas is cooled by enhanced spray, desulfurization and dust removal at the same time, and then fully deodorized, decomposed purified by the UV device and the flue gas is reach to the standard |

Please Feel free to give your inquiry in the form below.we will reply you in 24 hours.