| Final Product | Usage |

| Pyrolysis oil (40-55%) | 1. Can be reprocessed by oil distillation machine to extract diesel if the customers want to sell it at a better price. 2. The diesel can be used as fuel oil to many large types of machinery 3. Can be recycled to the furnace for heating the reactor 4. Can be sold directly, widely used in ceramic factory, cement factory, steel factory and so on 5. Can be used directly in the heavy oil generator to get electricity |

| Carbon black (30-35%) | 1. Can be reprocessed through carbon black grinding plant, such as use in rubber industry , black dye, paint 2. Used in tire manufacturing, cables, conveyor belts, soles and other rubber and plastic products 3. To make briquette and construction brick 4. Sell directly |

| Steel wires from waste tire(10%-15%) | 1. Sell directly on the market 2. Recycle them in steel factories to make steel bars |

| Combustible gas(8%-10%) | 1. Can be reused to supply heat for the pyrolysis reactor 2. Can generator to power electricity 3. Compressed into liquid gas |

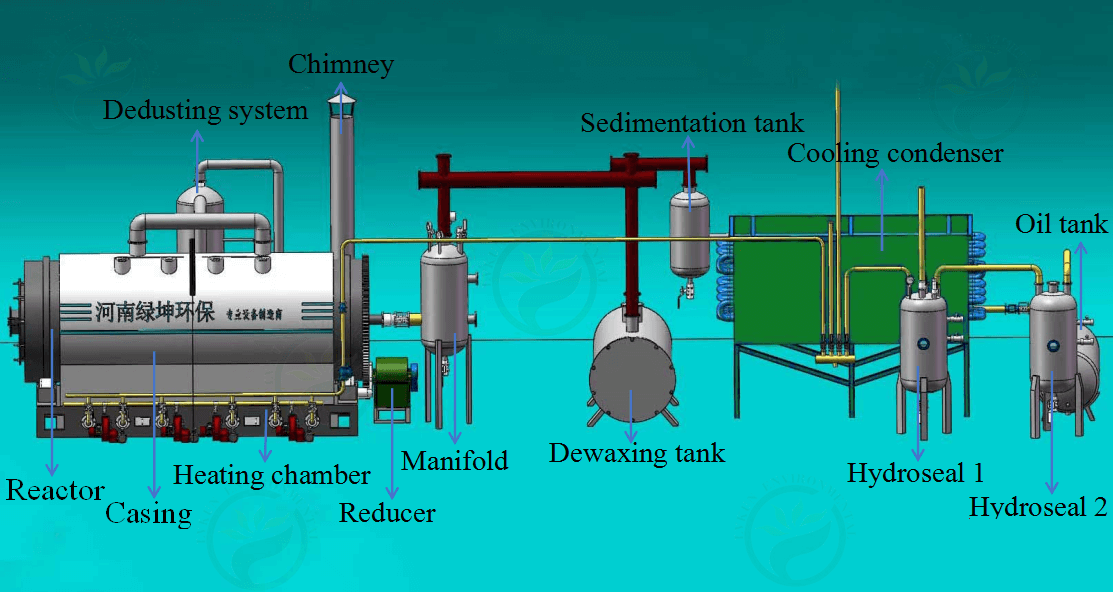

| Item | Function |

| Reactor | Q345 steel plate and new insulation material ,Fast heating, fast cooling, long service life, greatly improve production efficiency,Raw material in high temperature pyrolysis under full closed condition,convert to fuel oil |

| Manifold | On the one hand, it can make the pyrolysis furnace in a slightly negative pressure state, on the other hand, it can realize the separation of flue gas and heavy oil |

| Oil Cooling | Large and enough cooling area to gurantee the effection of oil cooling , and takes short time to overhaul compared with other suppliers |

| Dedusting | Ensure the flue emmission meet European Standard |

| Hydroseal | Two-stage hydroseal design,Prevent fire back to oil gas pipes , ensure pyrolysis machine and staff’s safety |

| Discharging | To discharging carbon black automatically with full -close ,more environmental |

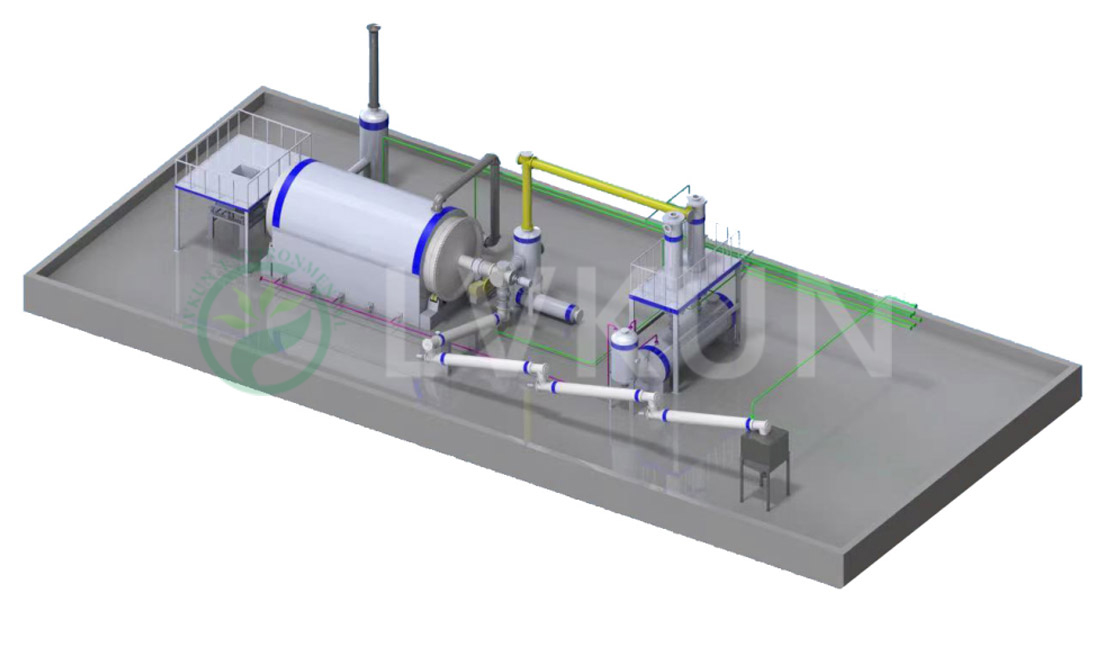

| Model | LKP-6 | LKP-8 | LKP-12 | LKP-15 | LKP-20 | LKP-40 |

| Size of Reactor(M) | D2.2*L6.0 | D2.8*L6.2 | D2.8*L7.1 | D2.8*L8.0 | D2.8*L8.8 | L26*W1.8*H2.5 |

| Daily Capacity | 5-6T/D | 8T/D | 10-12T/D | 15T/D | 16-20T/D | 30-40T/D |

| Power | 24kw/h | 30kw/h | 36kw/h | 40kw/h | 56kw/h | 108kw/h |

| Working Method | Intermittent/Batch | Semi-continuous | Full-continuous | |||

| Heating Material | Natural gas/Oil/Wood/Coal/LPG and so on | |||||

| Reactor Thickness | 14mm/16mm/18mm | |||||

| Rotate Speed of Reactor | 0.4turn/minute | |||||

| Cooling Method | Water cycling cooling | |||||

| Labor Required | 4-6 person in two or three shifts | |||||

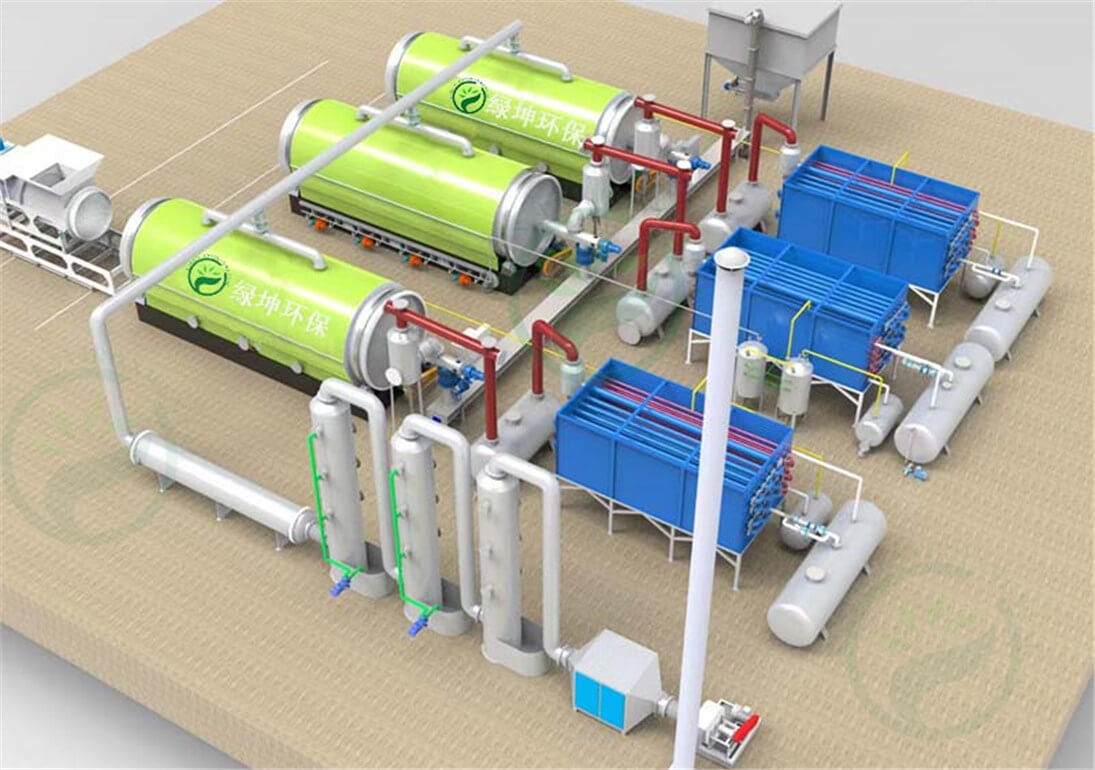

| Item | Lvkun Batch Plant Unique Advantage |

| Low Investment Of High Profit | Custom Capacity 6T-15T per day , can be loading with whole tire , no need for shredding with low investment cost |

| Simple Operation Of Less Labor | Modular design condenser , more convenient for installation,high automatic less demand for labor |

| Free Installation | The Mini pyrolysis and distillation plant already finished installation and testing in our factory before delivery |

| Safe and Operation Reliable | Lvkun unique hot airtight technology, safe and reliable operation, low labor requirements |

| High Quality Product Output | Lvkun Unique non-coking technology, so that the material is heated evenly, fully cracked and high product quality |

| EU and US Emission Standard | Emission gas of the production line has been tested, and all emission indicators comply with EU and US EPA standards |

| Low Operation Cost | Unique waste heat recycling technology, sync gas is used as fuel for heating of pyrolysis reactor to achieve self-sufficiency |

| Low Energy consumption and Long Life | Third-generation heating technology, low energy consumption,improves oil yield and quality, long-term stable operation extends life the equipment |

| PLC Control | The whole production line adopts PLC control, prompts and alarms to ensure safe operation of equipment |

China.plastic pyrolysis project

China.plastic pyrolysis project China.Tire pyrolysis project

China.Tire pyrolysis project China.Tire pyrolysis project

China.Tire pyrolysis project Cambodia.Tire pyrolysis project

Cambodia.Tire pyrolysis project China Tire pyrolysis project

China Tire pyrolysis project Thailand.Tire pyrolysis project

Thailand.Tire pyrolysis projectPlease Feel free to give your inquiry in the form below.we will reply you in 24 hours.