| Item | Description Of Pyrolysis Carbon Black |

| The crude carbon black after pyrolysis | Waste tyres after pyrolysis, we can get metal parts, fuel oil, steelwire and carbon black. Metal and gas can be recycled. Fuel oil can be distilled into diesel . Carbon black can be further processed into different sizes, and broadly used in rubber and painting industry. As one of the pyrolysis products, pyrolysis carbon black accounts for about 30%-35% of the total pyrolysis products. The crude carbon black after pyrolysis of tyre is black powder like solid matter, the weight is extremely light, and the density is only about 0.56gm/cc. It is easy to fly into the air and cause pollution. It needs to be transported and stored in a closed environment |

| Carbon black itself can be deep processing | Carbon black itself can be reused, but if it is not properly treated, it will easily cause secondary pollution and waste of resources. Therefore, the high-value utilization of pyrolysis carbon black has a bright future and a huge market. After deep processing, it will increase the profitability of the tyre pyrolysis industry. The carbon black deep processing equipment provided by lvkun environmental can increase the value of carbon black |

| Item | Carbon Black Treatment After Usage |

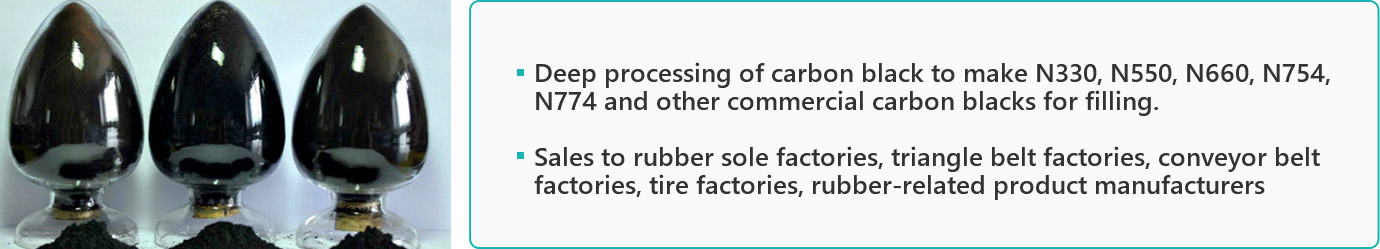

| N550 | This product is suitable for natural rubber and various synthetic rubbers. Reinforcement performance, elasticity and recovery are better. Mainly used in tire cord rubber, sidewalls, inner tubes, and extrusion and calendering products |

| N660 | This product is suitable for all kinds of rubber, with high tear resistance, small deformation, good elasticity and resistance to yaw. Mainly used for tire and wheel curtain tapes, inner tubes, bicycles, hoses, cables, shoes, calendered products, model products, etc |

| N774 | This product is suitable for all kinds of rubber, with tear resistance, heat resistance, cold resistance and oil resistance. Its characteristic is that it can be filled in large quantities and the rubber material has good processing performance. Used in tire cords, inner tubes, footwear and calendered products, natural rubber, nitrile rubber products, both reinforcing and filling functions |

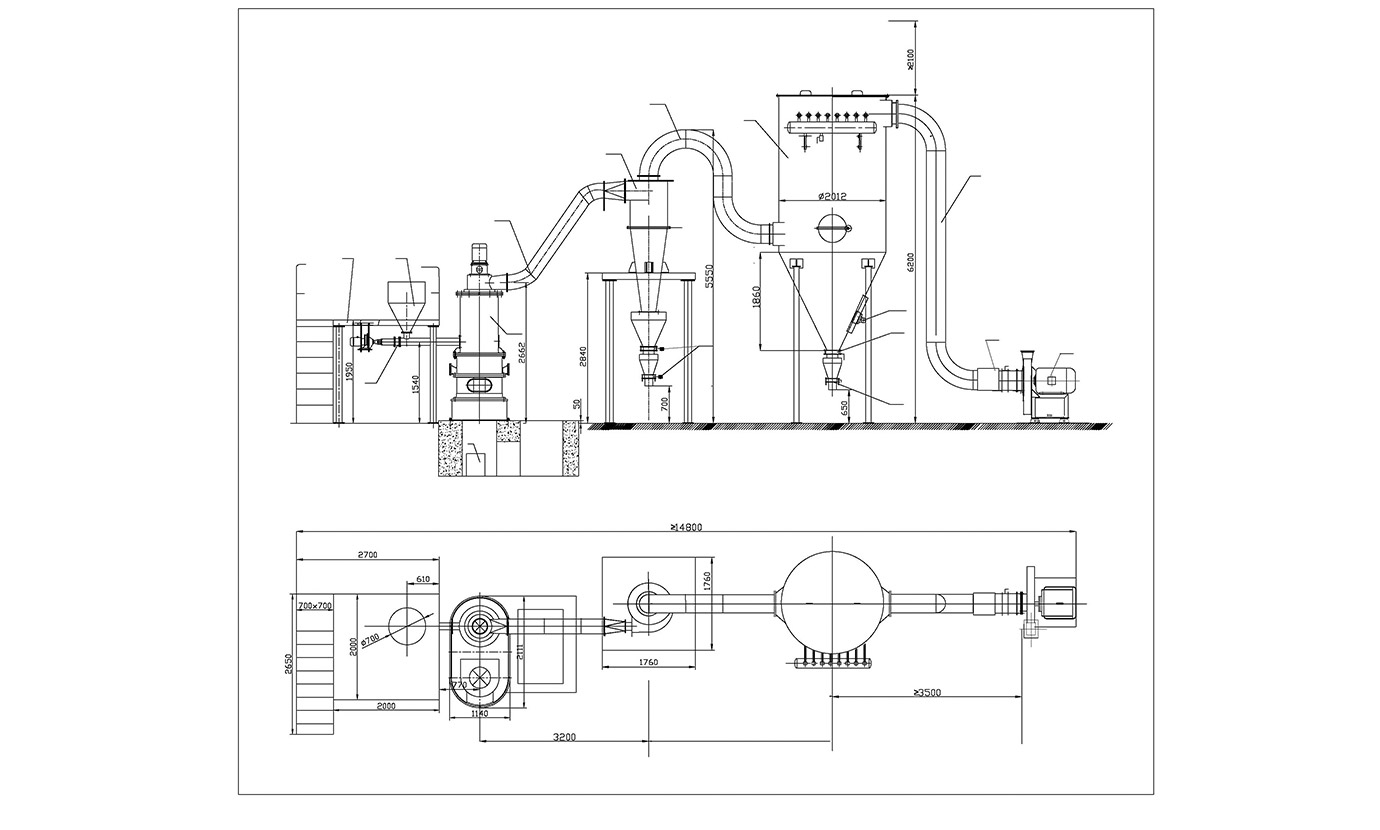

| Model | LKC600 | LKC800 | LKC1000 | LKC1200 | LKC1400 |

| Finished Product Fineness D100(<um) | 45 | 45 | 45 | 45 | 45 |

| 325 Mesh Sieve Residue | <0.01% | <0.01% | <0.01% | <0.01% | <0.01% |

| Grain Type Size(mm) | 0.5-2.5 | 0.5-2.5 | 0.5-2.5 | 0.5-2.5 | 0.5-2.5 |

| Capacity(10,000tons/year) | 0.3-0.5 | 0.5-0.8 | 0.9-1.7 | 1.3-2 | 1.8-3 |

| Power(kw) | 30 | 54 | 90 | 130 | 200 |

| Item | Lvkun Deep Processing Process Flow |

| Pyrolysis | Using pyrolysis equipment under high temperature,the coarse carbon black is pyrolysis in the form of negative pressure and part of the corresponding ash is neutralized |

| Iron removal | The automatic high-magnetic iron remover further separates the steel wires from the carbon black |

| Ultra-fine grinding | The ultra-fine grinding classifier grinds the coarse carbon black to meet the required fineness d100 of the filler <45um, and the residue on the 325 mesh sieve <0.001% |

| Granulation | Make good carbon black ultrafine powder by adding a certain amount of water and binder into carbon black particles that do not affect market applications, and optimize the packaging process |

| Drying | The water added quantitatively during the drying and granulation process |

| Conveying and packaging | According to the requirements of the production process, the entire process is automated for conveying and warehousing; combined with terminal application customization, 20-25kg small bag packaging and 750-1000kg ton bag packaging are implemented |

Please Feel free to give your inquiry in the form below.we will reply you in 24 hours.