2-3tons capacity mini pyrolysis plant is most popular ! Free installation testing in our factory and easier delivery by 1* 40HQ container ! When you get oil sample from this pyrolysis system , you can test the oil quality of different raw materials for future big capacity!

| Final Product | Usage |

| Pyrolysis oil (40-55%) | 1. Can be reprocessed by oil distillation machine to extract diesel if the customers want to sell it at a better price. 2. The diesel can be used as fuel oil to many large types of machinery 3. Can be recycled to the furnace for heating the reactor 4. Can be sold directly, widely used in ceramic factory, cement factory, steel factory and so on 5. Can be used directly in the heavy oil generator to get electricity |

| Carbon black (30-35%) | 1. Can be reprocessed through carbon black grinding plant, such as use in rubber industry , black dye, paint 2. Used in tire manufacturing, cables, conveyor belts, soles and other rubber and plastic products 3. To make briquette and construction brick 4. Sell directly |

| Steel wires from waste tire(10%-15%) | 1. Sell directly on the market 2. Recycle them in steel factories to make steel bars |

| Combustible gas(8%-10%) | 1. Can be reused to supply heat for the pyrolysis reactor 2. Can generator to power electricity 3. Compressed into liquid gas |

| Item | Function |

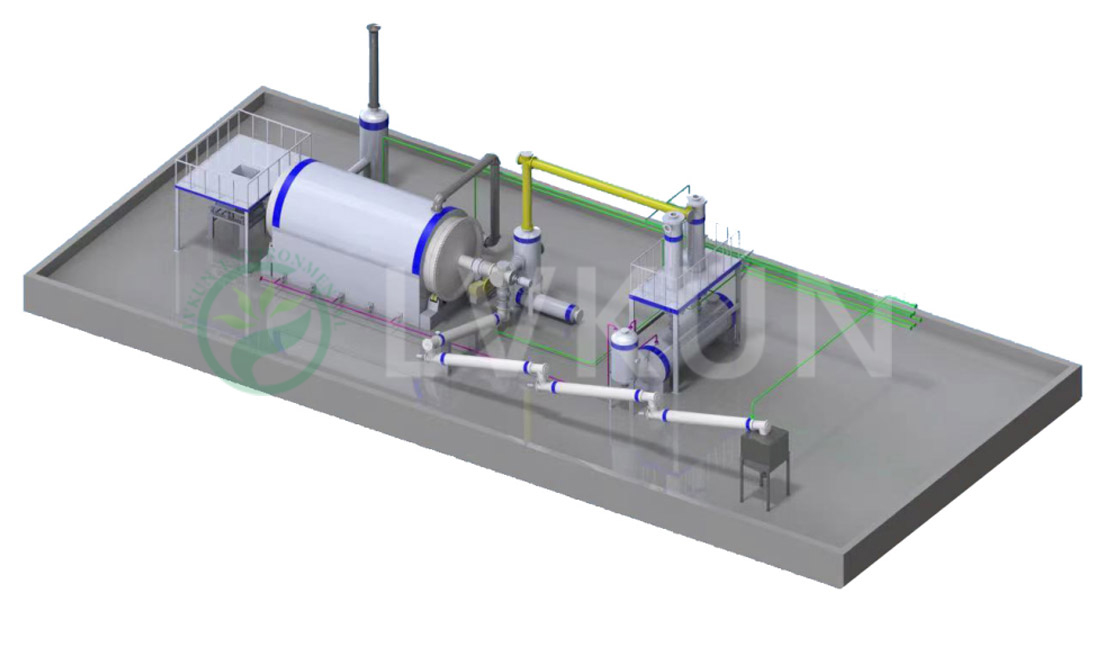

| Reactor | Q345 steel plate and new insulation material,Raw material in high temperature pyrolysis under full closed condition,convert to fuel oil |

| Manifold | On the one hand, it can make the pyrolysis furnace in a slightly negative pressure state, on the other hand, it can realize the separation of flue gas and heavy oil. |

| Oil Cooling | large and enough cooling area to gurantee the effection of oil cooling , and takes short time to overhaul compared with other suppliers |

| Dedusting | ensure the flue emmission meet European Standard |

| Hydroseal | Two-stage hydrosea design,prevent fire back to oil gas pipes , ensure pyrolysis machine and staff’s safety |

| Discharging | to discharging carbon black automatically with full -close ,more environmental |

| Model | LKP-3 |

| Size of Reactor | D1400*L4000mm |

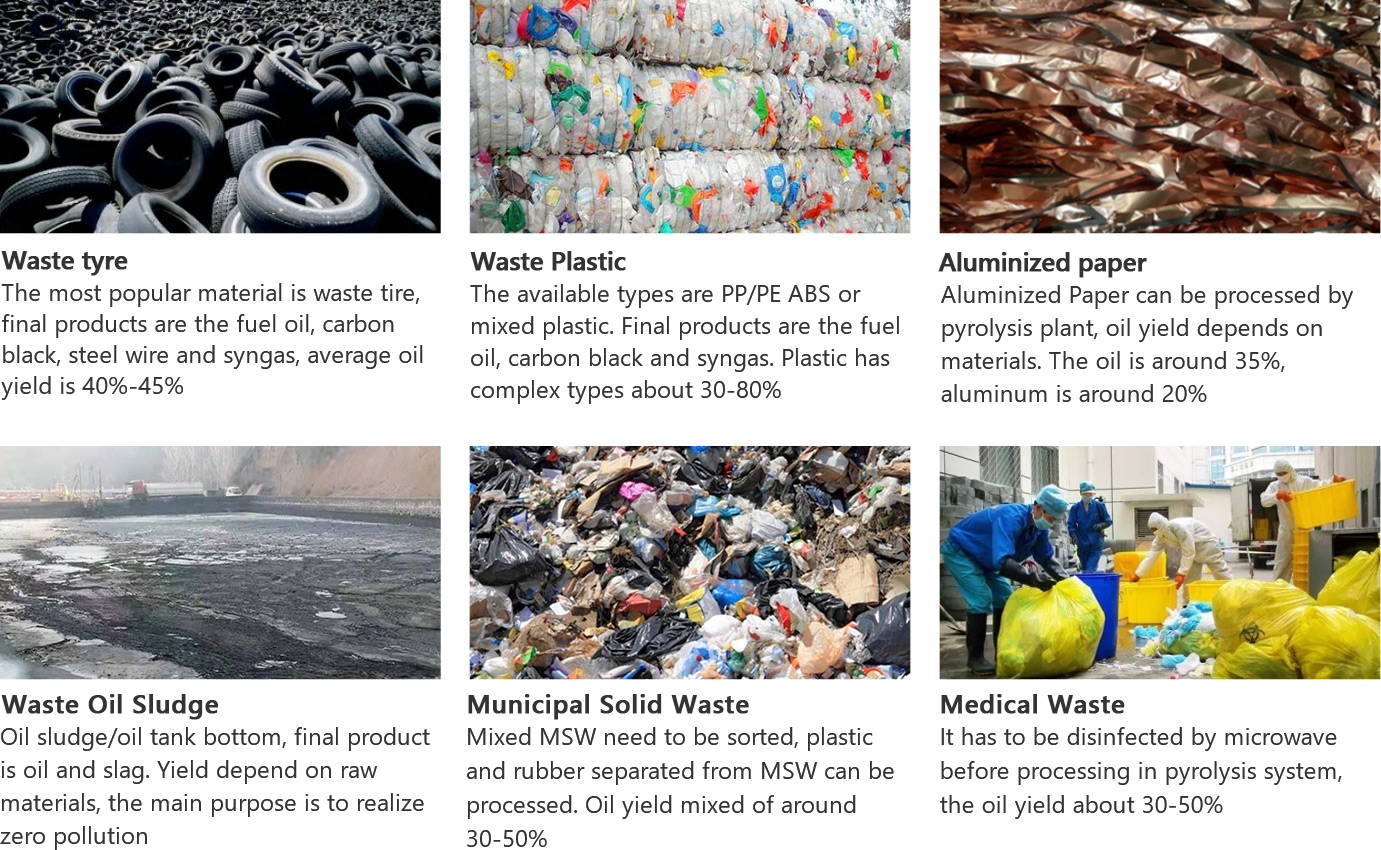

| Daily Capacity | Plastic: ≤3T/ Whole tyre: ≤2T/ Rubber particles: ≤3T/ Oil sludge: ≤3T/D |

| Power | 15kw/h |

| Working Method | Intermittent/Batch |

| Heating Material | Natural gas/Oil/Wood/Coal/LPG and so on |

| Reactor Thickness | 12mm/16mm/18mm |

| Rotate Speed of Reactor | 0.4turn/minute |

| Cooling Method | Water cycling cooling |

| Container Required | 1*40HQ |

| Item | Lvkun Mini Plant Unique Advantage |

| Automatic Screw Discharging | With automatic carbon screw discharging system for avoiding fly ash pollution and more safety as well ! No need labor open any door when discharging...some supplier may supply cheap design like discharging from the loading door, it would be need waiting more time for cooing system below 50 degree and open the door by manual.. Our machine design meet worker safety and environmental protection required |

| Two Batch One Day | 1hours feeding, 2hours preheating, 2-3hours production, 4hours cooling in 100-120 degree, 30minute discharging..10hours can finish one batch, so you can feeding two batch one day |

| Free Installation | The Mini pyrolysis and distillation plant already finished installation and testing in our factory before delivery |

| Low Transportation Cost | Integrated into a production module, one container can be transported away |

| Low Labor Cost | Two worker to operate the feeding and discharging slag |

| Simple Operation | Only need connect power and water when get pyrolysis plant. We will doing a video installation and training, organize a installation manual for you |

South Africa LKP-2

South Africa LKP-2 Thailand LKP-3

Thailand LKP-3 The Dominican Republic LKP-3

The Dominican Republic LKP-3  Bangladesh LKP-1

Bangladesh LKP-1  Brizil LKP-3

Brizil LKP-3  Chile LKP-2

Chile LKP-2Please Feel free to give your inquiry in the form below.we will reply you in 24 hours.